Leather is a fantastic medium for making award medallions.

It is easy to work with and durable. Nice medallions are easy to make even with

a limited selection of tools and the amount of leather needed allows the

crafter to work with cheap (or even free) leather scraps. This is a short

tutorial on how I make my leather award medallions. Making leather medallions is a fairly painless process. Follow all the normal rules for using sharp objects and chemicals (leather dye, paint, etc.) and you will be fine.

Leather medallions are ridiculously durable so they are a great option for people who want to wear an award in high use environments like the list field. Leather is also very forgiving when it comes to inexperienced leather workers. A finely detailed finished product might take some practice but the basic product is durable, safe to wear, and pleasing to the eye. The average build time for a medallion with a moderately complex design (going from raw leather to painted) is about 4 days. A lot of this is drying time (water after tooling, dying, and painting) so working on multiple medallions is a good idea. It won’t cut down the production time but you will increase output. It is possible to shorten the production time, but rushing will often yield a lower quality product.

Materials:

To make my medallions I use 8-9 ounce vegetable-tanned cowhide. In terms of

inches, 8-9 ounce leather is just over 1/8 of an inch thick. You need it to be

thick enough to tool but not so thick that the finished project looks clunky.

Veg-tanned cowhide is available from several on-line sellers (Tandy leather,

for example) or if you are fortunate enough, at a local leather shop. Leather

can be on the expensive side (as much as $8 US per square foot), but the nice

part of medallions is that they don’t require much leather (2 inch diameter on

average). Local and on-line sellers will often offer small scraps for a reduced

price, or if you know a person who works with leather, most of them have an

odds and ends bin that is useless to them but is a treasure trove for a

medallion maker. Pro tip: leather scraps are cheap, but make sure you are using

fresh leather. Using old or imperfect leather will result in a lower quality

finished product.

Construction:

Trace or draw the

design onto the leather. This can be done free hand or with transfer paper. I always draw the design on the leather before cutting the medallion "shape". This way you can adjust the final size of the medallion to achieve the best cosmetic effect. I find 1.5 to 2.0 inches is the best size. The size also depends on your tooling ability. If you are not up to small detail work it is best to make the medallion a bit bigger. The marks left by the pencil/transfer paper will not affect the final project as they will be covered by leather dye and paint.

Now cut the medallion to shape. Most of my medallions are circular (I find that most Kingdoms/Baronies use circular medallions but always check before cutting). I use a simple circle template to draw the circle and then cut the medallion to shape with leather shears or a craft knife.

Pro tip: When using a larger piece of leather cut your projects into smaller chunks before trying to cut out the medallion. You will waste a bit of leather but it makes cutting easier and more precise.

Tooling:

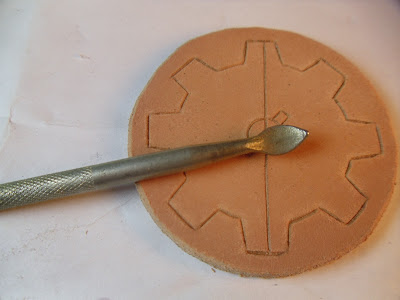

Next I use a swivel knife to cut the design into the

leather. Now I start on the tooling taking the medallion from a simple 2-D design and working it into a 3-D design. Tooling serves a cosmetic function (making the medallion visual appealing) but also helps with durability by created a dynamic surface that paint can adhere to.

To save on some bandwidth here is a video on the use and care of swivel knives. Video by Tandy Leather. The video is a bit dry but it covers a lot of the basics.

Here is what the medallion looks like after the swivel knife is applied.

Next I use a simple leather working tool called a “spoon” to

shape the leather and give the design a 3D effect. (please pardon that the design switched between photos). This is done by wetting the

leather with water to make it malleable and then pressing the design into the

leather with the spoon. When the leather dries, the design is permanent. There are a ton of different leather working tools that can

be used for tooling but I do about 95% of my work with the swivel knife and

spoon. The spoon has two ends (as seen below) and allows for a variety of detailing. You can also use the spoon to smooth the edges of the medallion.

Here is a quick and simply video about using a spoon.

I like video but I can't speak for the company that created it or their products. Please use the video as a guide only. Shop with caution :)

This is what the design looks like once the spoon has been applied.

Finishing:

Once the leather is tooled and dried, I color the medallion with

leather dye. I use simple Tandy leather dye:

For most medallions I use black as a base color. Always check with your Kingdom/Barony/Group about the proper colors to use for each award. There are other colors of leather dye that you can use as needed. I dye the main body (including back and edges) to give the medallion an even color. The Dye also helps protect the leather from wear, sweat, and weather.

Once the leather dye is dry I paint the details with acrylic hobby

paint. My paint of choice is the Games Workshop brand of “base” paints. They

look good and have almost full coverage with one or two coats (even over black leather

dye).The paints are water based and I apply them with simply hobby paint brushes found at any craft store.

Pro Tip: Do not rush when applying the paint. Apply the paint in thin, even coats and allow time to dry between layers. Rushing will cause the paint to build up in thick uneven layers. This will not only reduce the cosmetic look but can also result in the paint cracking.

The medallions after the paint is applied:

To protect the paint and the leather I apply a quick coat of Super Shene leather finish.

Mounting:

Finally I use a leather punch to put a hole in the medallion. I place a simple jump ring into that and then use cording, string, or a chain to make the medallion wearable.

Questions:

If people have questions feel free to contact me directly,

either on the Book of Face at “Lance Magnus Kazmark” or by email (magnusofnarnia@gmail.com).